| Product Name |

Size Type |

Machinable Dimensions (Can Be Classified According To Size), With Tolerances |

| Neodymium Block Magnet |

L/W |

1、0.2mm<L/W≤5.00mm,Tolerances±0.02mm

|

|

2、5.0mm<L/W≤20.0mm,Tolerances±0.03mm

|

3、20.0mm<L/W≤85.0mm,Tolerances±0.04mm

|

| H |

1、0.2mm<H≤3.00mm,Tolerances±0.02mm

|

|

2、3.00mm<H≤10.0mm,Tolerances±0.03mm

|

3、H>10.0mm,Tolerances±0.05mm

|

| Flatness |

1、L×W≤25.0mm²,Flatness±0.02mm |

| 2、25.0mm²<L×W≤400.0mm²,Flatness±0.03mm |

| 3、400.0mm²<L×W<5600.0mm²,Flatness±0.05mm |

| Parallelism |

1、0.20mm<L/W≤5.00mm,Parallelism±0.02mm |

| 2、5.00mm<L/W≤30.0mm,Parallelism±0.03mm |

| 3、30.0mm<L/W≤75.0mm,Parallelism±0.05mm |

| 4、L/W>75.0mm,Parallelism±0.10mm |

| C Angle |

|

| C≥0.1mm |

|

|

|

|

|

|

| R Angle |

|

| R≥0.1mm |

|

|

|

Advantages of Square NdFeB Magnets

1. High Magnetic Strength:

Square NdFeB magnets are known for their high magnetic strength, which makes them an excellent choice for EV wheel hub motors. They have a maximum energy product (BHmax) that is five times greater than that of ferrite magnets. This high magnetic strength enables better torque and acceleration of the motor, thereby improving the overall performance of the EV.

2. Efficient Power Transfer:

The use of square NdFeB magnets also improves the efficiency of the EV motor since they generate less eddy current than other types of magnets. This is because the square shape allows for a more even distribution of the magnetic field, leading to less power loss due to eddy currents.

3. Compact Size:

Square NdFeB magnets are also preferred for EV wheel hub motors because of their compact size. This enables them to be easily integrated into the wheel hub without increasing the size or weight of the motor. In addition, this also allows for a more compact design of the EV, which is highly desirable for urban driving conditions.

Disadvantages of Square NdFeB Magnets

1. High Cost:

Despite their numerous advantages, one major disadvantage of square NdFeB magnets is their high cost compared to other types of magnets. This high cost is due to the complex manufacturing process and the high price of rare earth materials.

2. Low Operating Temperature:

Square NdFeB magnets have a relatively low operating temperature range of around 80°C. This means that they need to be treated with care during operation to avoid overheating and demagnetization, which can cause reduced performance and even motor failure.

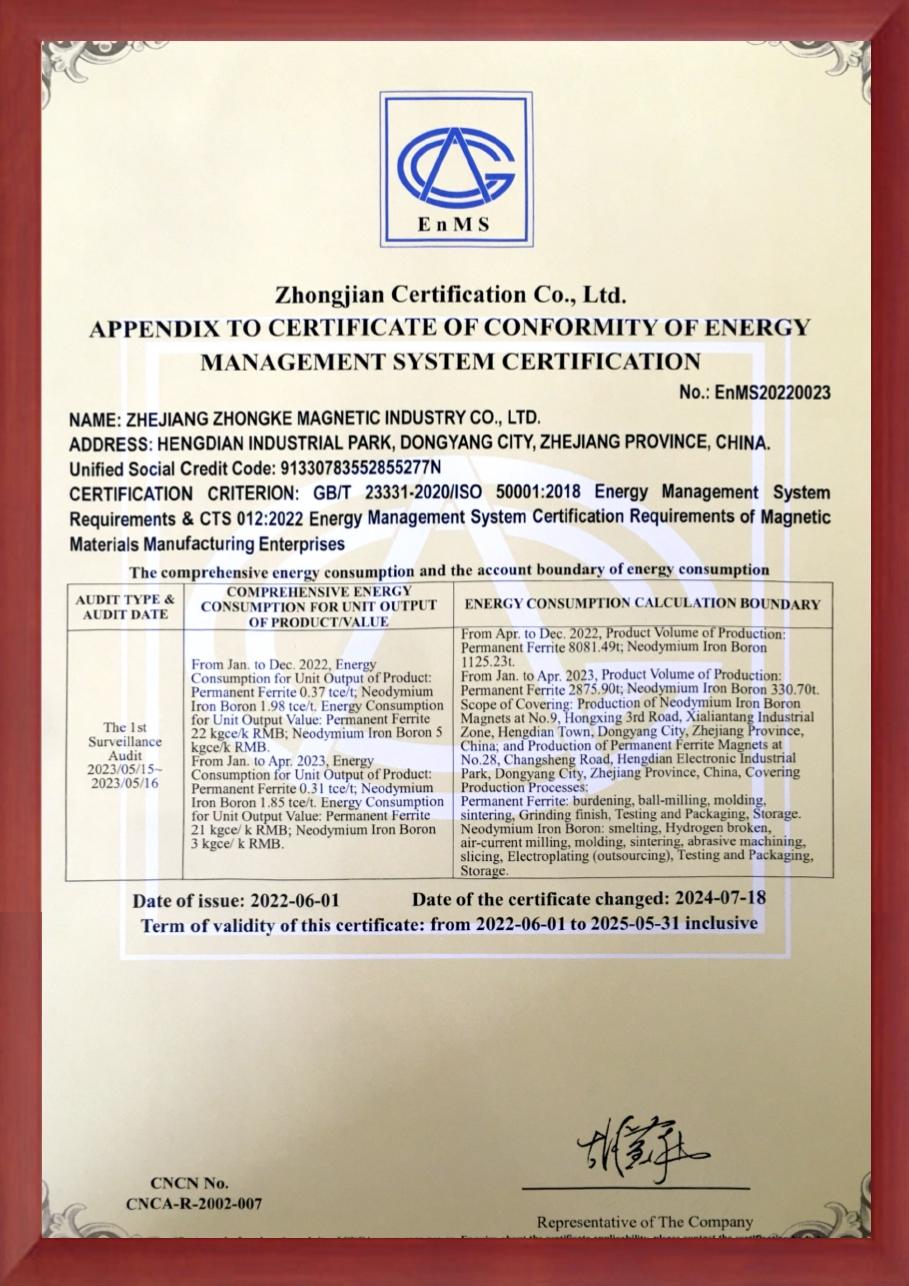

Zhejiang Zhongke Magnetic Industry Co., Ltd., a leading manufacturer of NdFeB magnets in China, excels in manufacturing square-shaped NdFeB magnets due to its advanced technology and strict quality control. Advantages of Zhejiang Zhongke Magnetic Industry Co., Ltd. in Manufacturing Square NdFeB Magnets:

1. Advanced Technology:

Zhejiang Zhongke Magnetic Industry Co., Ltd. has invested in advanced technology for the manufacture of NdFeB magnets, which ensures the precision and consistency of the magnets. This technology improves the efficiency, magnetic strength, and durability of the magnets, making them ideal for use in EV wheel hub motors.

2. Strict Quality Control:

Zhejiang Zhongke Magnetic Industry Co., Ltd. has a sophisticated quality control system that ensures that each batch of magnets meets all the required technical specifications. This system includes the use of advanced testing equipment and conducting rigorous quality tests at every stage of production.

3. Customized Magnets:

Zhejiang Zhongke Magnetic Industry Co., Ltd. can also provide customized magnets for specific applications. This allows customers to get the exact magnet specifications that they require, ensuring top performance and quality.

Square NdFeB magnets are key components in electric vehicle wheel hub motors. While they offer numerous advantages such as high magnetic strength, efficient power transfer, and compact size, they also have some disadvantages like high cost and low operating temperature. Zhejiang Zhongke Magnetic Industry Co., Ltd. excels in manufacturing square NdFeB magnets due to its advanced technology and strict quality control, making them an ideal choice for use in EV wheel hub motors.

English

English Español

Español Deutsch

Deutsch Tiếng Việt

Tiếng Việt

+86-15857968349

+86-15857968349

WeChat/Zalo/whatsApp: +86-15857968349(Jerry Ma)

WeChat/Zalo/whatsApp: +86-15857968349(Jerry Ma)

Email: mahy@dymagnet.com

Email: mahy@dymagnet.com  No.9,Hongxing 3rd Road,Hengdian Industrial Park,Dongyang City,Zhejiang,China.

No.9,Hongxing 3rd Road,Hengdian Industrial Park,Dongyang City,Zhejiang,China.