+86-15857968349

+86-15857968349

mahy@dymagnet.com

mahy@dymagnet.com

| Product Name | Size Type | Machinable Dimensions (Can Be Classified According To Size), With Tolerances |

| Neodymium Cyliner Magnet |

Inner And Outer Diameter/Concentricity

|

1、Cylindrical Diameter≤65mm,Tolerances±0.10mm

|

|

2、Cylindrical Diameter≤110mm,Tolerances±0.10mm

|

||

|

3、Height (Usually)≤45mm,Tolerances±0.10mm

|

|

Sintered NdFeB Magnet Inspection Standards |

|||||||||

|

GRADE Performance grade |

Residual Magnetic Induction Intensity (Br) |

Magnetic Coercivity (HCB) |

Intrinsic Coercivity (HCJ) |

Maximum Magnetic Energy Product (BH)max |

Maximum Operating Temperature Tw L/D = 0.7 |

||||

|

Minimum Value |

Minimum Value |

Minimum Value |

Range |

||||||

|

T |

kGs |

kA/m |

kOe |

kA/m |

kOe |

kA/m³ |

MGOe |

°c |

|

|

N28ZH |

1.04 |

10.4 |

772 |

9.7 |

3184 |

40 |

207 ~ 230 |

26 ~ 29 |

250 |

|

N44AH |

1.3 |

13 |

971 |

12.2 |

2786 |

35 |

326~358 |

41~45 |

230 |

|

N42AH |

1.29 |

12.9 |

963 |

12.1 |

2786 |

35 |

318 ~ 342 |

40 ~ 43 |

230 |

|

N40AH |

1.26 |

12.6 |

939 |

11.8 |

2786 |

35 |

302 ~ 326 |

38 ~ 41 |

230 |

|

N35AH |

1.17 |

11.7 |

868 |

10.9 |

2786 |

35 |

263 ~ 287 |

33 ~ 36 |

230 |

|

N30AH |

1.08 |

10.8 |

804 |

10.1 |

2786 |

35 |

223 ~ 247 |

28 ~ 31 |

230 |

|

N42TH |

1.29 |

12.9 |

957 |

11.8 |

2627 |

33 |

318 ~ 342 |

40 ~ 43 |

220 |

|

N40TH |

1.26 |

12.6 |

930 |

11.5 |

2627 |

33 |

302 ~ 326 |

38 ~ 41 |

220 |

|

N38TH |

1.23 |

12.3 |

910 |

11.1 |

2627 |

33 |

287 ~ 310 |

36 ~ 39 |

220 |

|

N35TH |

1.18 |

11.8 |

876 |

11 |

2786 |

35 |

263 ~ 287 |

33 ~ 36 |

220 |

|

N33TH |

1.13 |

11.3 |

844 |

10.6 |

2786 |

35 |

247 ~ 270 |

31 ~ 33 |

220 |

|

N30TH |

1.1 |

11 |

796 |

10 |

2786 |

35 |

223 ~ 247 |

28 ~ 31 |

220 |

|

N28TH |

1.05 |

10.5 |

756 |

9.5 |

2786 |

35 |

207 ~ 230 |

26 ~ 29 |

220 |

|

N45EH |

1.33 |

13.3 |

995 |

12.5 |

2308 |

29 |

342 ~ 366 |

43 ~ 46 |

200 |

|

N42EH |

1.29 |

12.9 |

957 |

11.8 |

2308 |

29 |

318 ~ 342 |

40 ~ 43 |

200 |

|

N40EH |

1.26 |

12.6 |

930 |

11.5 |

2388 |

30 |

302 ~ 326 |

38 ~ 41 |

200 |

|

N38EH |

1.23 |

12.3 |

910 |

11.1 |

2388 |

30 |

287 ~ 310 |

36 ~ 39 |

200 |

|

N35EH |

1.18 |

11.8 |

876 |

11 |

2388 |

30 |

263 ~ 287 |

33 ~ 36 |

200 |

|

N33EH |

1.13 |

11.3 |

844 |

10.6 |

2388 |

30 |

247 ~ 270 |

31 ~ 33 |

200 |

|

N30EH |

1.1 |

11 |

796 |

10 |

2388 |

30 |

223 ~ 247 |

28 ~ 31 |

200 |

|

N28EH |

1.05 |

10.5 |

756 |

9.5 |

2388 |

30 |

207 ~ 230 |

26 ~ 29 |

200 |

|

N52UH |

1.42 |

14.2 |

1018 |

12.8 |

1911 |

24 |

390 ~ 422 |

49 ~ 53 |

180 |

|

N50UH |

1.39 |

13.9 |

1018 |

12.8 |

1911 |

24 |

374 ~ 406 |

47 ~ 51 |

180 |

|

N48UH |

1.37 |

13.7 |

1018 |

12.8 |

1911 |

24 |

358 ~ 390 |

45 ~ 49 |

180 |

|

N45UH |

1.33 |

13.3 |

995 |

12.5 |

1911 |

24 |

342 ~ 366 |

43 ~ 46 |

180 |

|

N42UH |

1.29 |

12.9 |

957 |

11.8 |

1990 |

25 |

318 ~ 342 |

40 ~ 43 |

180 |

|

N40UH |

1.26 |

12.6 |

930 |

11.5 |

1990 |

25 |

302 ~ 326 |

38 ~ 41 |

180 |

|

N38UH |

1.23 |

12.3 |

910 |

11.1 |

1990 |

25 |

287 ~ 310 |

36 ~ 39 |

180 |

|

N35UH |

1.18 |

11.8 |

876 |

11 |

1990 |

25 |

263 ~ 287 |

33 ~ 36 |

180 |

|

N33UH |

1.13 |

11.3 |

844 |

10.6 |

1990 |

25 |

247 ~ 270 |

31 ~ 33 |

180 |

|

N30UH |

1.1 |

11 |

796 |

10 |

1990 |

25 |

223 ~ 247 |

28 ~ 31 |

180 |

|

N28UH |

1.05 |

10.5 |

756 |

9.5 |

1990 |

25 |

207 ~ 230 |

26 ~ 29 |

180 |

|

N52SH |

1.42 |

14.2 |

1018 |

12.8 |

1512 |

19 |

390 ~ 422 |

49 ~ 53 |

150 |

|

N50SH |

1.39 |

13.9 |

1018 |

12.8 |

1512 |

19 |

374 ~ 406 |

47 ~ 51 |

150 |

|

N48SH |

1.37 |

13.7 |

1018 |

12.8 |

1512 |

19 |

358 ~ 390 |

45 ~ 49 |

150 |

|

N45SH |

1.33 |

13.3 |

995 |

12.5 |

1592 |

20 |

342 ~ 366 |

43 ~ 46 |

150 |

|

N42SH |

1.29 |

12.9 |

957 |

11.8 |

1592 |

20 |

318 ~ 342 |

40 ~ 43 |

150 |

|

N40SH |

1.26 |

12.6 |

930 |

11.5 |

1592 |

20 |

302 ~ 326 |

38 ~ 41 |

150 |

|

N38SH |

1.23 |

12.3 |

910 |

11.1 |

1592 |

20 |

287 ~ 310 |

36 ~ 39 |

150 |

|

N35SH |

1.18 |

11.8 |

876 |

11 |

1592 |

20 |

263 ~ 287 |

33 ~ 36 |

150 |

|

N33SH |

1.13 |

11.3 |

844 |

10.6 |

1592 |

20 |

247 ~ 270 |

31 ~ 33 |

150 |

|

N30SH |

1.1 |

11 |

796 |

10 |

1592 |

20 |

223 ~ 247 |

28 ~ 31 |

150 |

|

N28SH |

1.05 |

10.5 |

756 |

9.5 |

1592 |

20 |

207 ~ 230 |

26 ~ 29 |

150 |

|

N55H |

1.45 |

14.5 |

1035 |

13 |

1274 |

16 |

406 ~ 438 |

51 ~ 55 |

120 |

|

N52H |

1.42 |

14.2 |

1035 |

13 |

1274 |

16 |

390 ~ 422 |

49 ~ 53 |

120 |

|

N50H |

1.39 |

13.9 |

1035 |

13 |

1274 |

16 |

374 ~ 406 |

47 ~ 51 |

120 |

|

N48H |

1.37 |

13.7 |

1018 |

12.8 |

1274 |

16 |

358 ~ 390 |

45 ~ 49 |

120 |

|

N45H |

1.33 |

13.3 |

995 |

12.5 |

1353 |

17 |

342 ~ 366 |

43 ~ 46 |

120 |

|

N42H |

1.29 |

12.9 |

957 |

12 |

1353 |

17 |

318 ~ 342 |

40 ~ 43 |

120 |

|

N40H |

1.26 |

12.6 |

930 |

117 |

1353 |

17 |

302 ~ 326 |

38 ~ 41 |

120 |

|

N38H |

1.23 |

12.3 |

910 |

11.4 |

1353 |

17 |

287 ~ 310 |

36 ~ 39 |

120 |

|

N35H |

1.18 |

11.8 |

876 |

11 |

1353 |

17 |

263 ~ 287 |

36 ~ 39 |

120 |

|

N33H |

1.13 |

11.3 |

844 |

10.6 |

1353 |

17 |

247 ~ 270 |

33 ~ 36 |

120 |

|

N30H |

1.1 |

11 |

796 |

10 |

1353 |

17 |

223 ~ 247 |

31 ~ 33 |

120 |

|

N28H |

1.05 |

10.5 |

756 |

9.5 |

1353 |

17 |

207 ~ 230 |

28 ~ 31 |

120 |

|

N55M |

1.45 |

14.5 |

995 |

12.5 |

1035 |

13 |

406 ~ 438 |

51 ~ 55 |

100 |

|

N52M |

1.42 |

14.2 |

995 |

12.5 |

1035 |

13 |

390 ~ 422 |

49 ~ 53 |

100 |

|

N50M |

1.39 |

13.9 |

1035 |

13 |

1114 |

14 |

374 ~ 406 |

47 ~ 51 |

100 |

|

N48M |

1.37 |

13.7 |

1012 |

12.7 |

1114 |

14 |

358 ~ 390 |

45 ~ 49 |

100 |

|

N45M |

1.33 |

13.3 |

971 |

12.2 |

1114 |

14 |

342 ~ 366 |

43 ~ 46 |

100 |

|

N42M |

1.29 |

12.9 |

938 |

11.8 |

1114 |

14 |

318 ~ 342 |

40 ~ 43 |

100 |

|

N40M |

1.26 |

12.6 |

910 |

11.4 |

1114 |

14 |

302 ~ 326 |

38 ~ 41 |

100 |

|

N38M |

1.23 |

12.3 |

876 |

11 |

1114 |

14 |

287 ~ 310 |

36 ~ 39 |

100 |

|

N35M |

1.18 |

11.8 |

860 |

10.8 |

1114 |

14 |

263 ~ 287 |

33 ~ 36 |

100 |

|

N33M |

1.13 |

11.3 |

796 |

10 |

1114 |

14 |

247 ~ 270 |

31 ~ 33 |

100 |

|

N30M |

1.1 |

11 |

796 |

10 |

1114 |

14 |

223 ~ 247 |

28 ~ 31 |

100 |

|

N28M |

1.05 |

10.5 |

756 |

9.5 |

1114 |

14 |

207 ~ 230 |

26 ~ 29 |

100 |

|

N55 |

1.45 |

14.5 |

836 |

10.5 |

875 |

11 |

406 ~ 438 |

51 ~ 55 |

80 |

|

N54 |

1.45 |

14.4 |

836 |

10.5 |

876 |

11 |

406 ~ 430 |

51 ~ 54 |

80 |

|

N52 |

1.42 |

14.2 |

860 |

10.8 |

960 |

12 |

390 ~ 422 |

49 ~ 53 |

80 |

|

N50 |

1.39 |

13.9 |

860 |

10.8 |

960 |

12 |

374 ~ 406 |

47 ~ 51 |

80 |

|

N48 |

1.37 |

13.7 |

860 |

10.8 |

960 |

12 |

358 ~ 390 |

45 ~ 49 |

80 |

|

N45 |

1.33 |

13.3 |

836 |

10.5 |

960 |

12 |

342 ~ 366 |

43 ~ 46 |

80 |

|

N42 |

1.29 |

12.9 |

836 |

10.5 |

960 |

12 |

318 ~ 342 |

40 ~ 43 |

80 |

|

N40 |

1.26 |

12.6 |

836 |

10.5 |

960 |

12 |

302 ~ 326 |

38 ~ 41 |

80 |

|

N38 |

1.23 |

12.3 |

836 |

10.5 |

960 |

12 |

287 ~ 310 |

36 ~ 39 |

80 |

|

N35 |

1.18 |

11.8 |

836 |

10.5 |

960 |

12 |

263 ~ 287 |

33 ~ 36 |

80 |

|

N33 |

1.13 |

11.3 |

796 |

10 |

960 |

12 |

247 ~ 270 |

31 ~ 34 |

80 |

|

N30 |

1.08 |

10.8 |

804 |

10.1 |

876 |

11 |

223 ~ 255 |

28 ~ 32 |

60 |

|

N30C |

1.08 |

10.8 |

804 |

10.1 |

716 |

9 |

223 ~ 255 |

28 ~ 32 |

60 |

|

N28 |

1.04 |

10.4 |

772 |

9.7 |

557 |

7 |

207 ~ 230 |

28 ~ 31 |

60 |

| Type Of Coating | Thickness | Exterior | Corrosion Resistance | Remark | |||||

| PCT | Salt Spray | Humidity and Temperature | Acid/Alkali | Oil | |||||

| Zn(White Zn) | √ | ≥5μm | Blue white | —— | ★★ | ★★★ | —— | ★ | |

| Zn(Color-plated Zn) | √ | ≥5μm | Iridescent | —— | ★★★ | ★★★★ | —— | ★ | |

| Ni+Cu+Ni | √ | ≥15μm | Silver White | ★★★ | ★★★★ | ★★★★★ | ★★★ | ★★★ | |

| Ni+Cu+Ni+Sn | ≥15μm | Silver White | ★★★★ | ★★★★ | ★★★★★ | —— | —— | Excellent Eelding Performance | |

| Chemic Ni | √ | ≥5μm | Silver White | ★★★★ | ★★★★★ | ★★★★★ | ★★★ | ★★★ | |

| Epoxy | √ | ≥12μm | Black or Gray | ★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★ | Poor Wear Resistance |

| Passivated | √ | ≤2μm | Black or Gray | —— | —— | ★★★ | —— | ★★★ | |

| Al | ≥3μm | Silver Gray | ★★★★ | ★★★ | ★★★★ | —— | ★★★ | High Binding Force | |

| Al+Epoxy | ≥15μm | Black or Gray | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | Poor Wear Resistance | |

| Zn+Al | ≥10μm | Silver White or Silver Gray | ★★★★★ | ★★★★★ | ★★★★★ | —— | ★★★★★ | ||

| Everluber | ≥5μm | Golden | ★★★★ | ★★★★ | ★★★★★ | ★★★★★ | ★★★★ | ||

| Teflon | ≥5μm | Black | ★★ | ★★★ | ★★★★★ | ★★★★★ | ★★★ | Good Wear Resistance | |

|

|

|

|

|

Disc Axial

|

Disc Diametrical

|

Cylinder Axial

|

Cylinder Diametrical

|

|

|

|

|

|

Ring Axial

|

Ring Diametrical

|

Ring Cylinder Axial

|

Ring Cylinder Diametrical

|

|

|

||

|

Block-Rectangle Thickness

|

Block-Rectangle Length

|

||

|

|

|

|

| Arc Width | Arc Height | Arc Diametrical | Arc Diametrical |

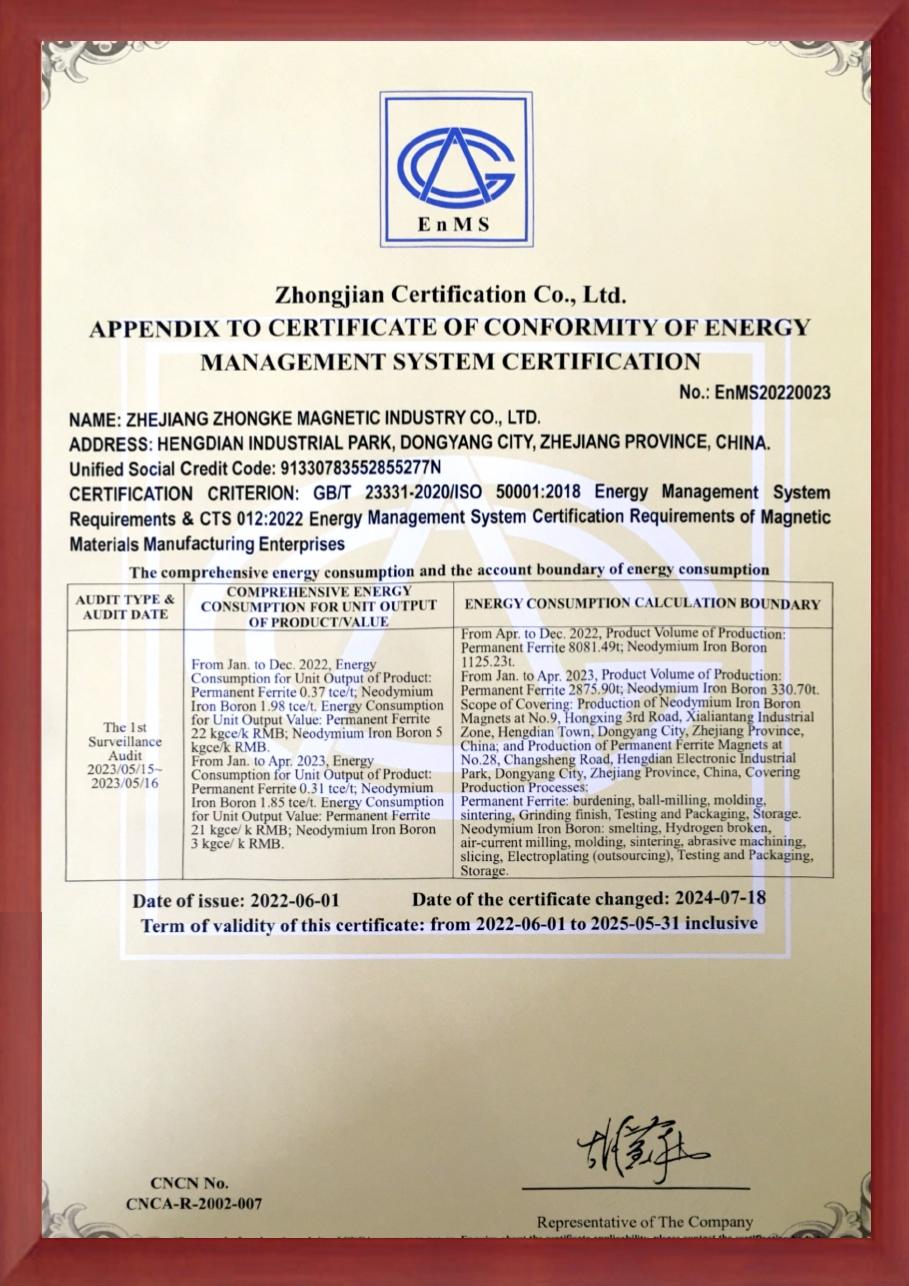

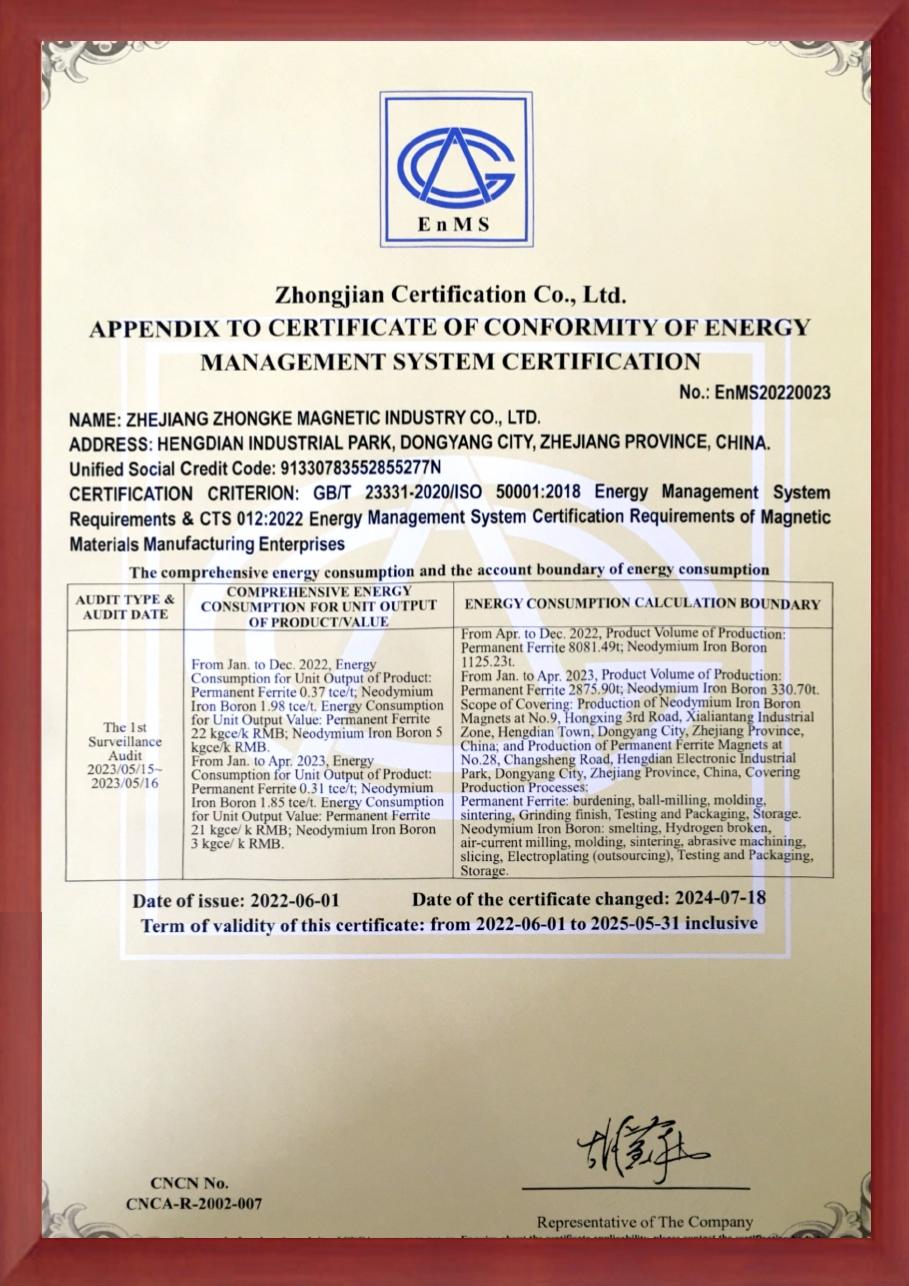

Zhejiang Zhongke Magnetic Industry Co., Ltd is leading rare earth rod magnets manufacturers and suppliers in China, The company's current production process of sintered NdFeB permanent magnet materials can be divided into two parts: the blank process (also known as the "front process" in the industry) and the finished product process (also known as the "post process" in the industry): the blank process is the praseodymium Neodymium metal, pure iron, ferroboron and other raw materials are used to make NdFeB blanks; the finished product process is to process NdFeB blanks by mechanical processing and surface treatment to obtain NdFeB magnets. We also OEM/ODM custom sintered neodymium cylinder magnets. The specific production process flow chart is as follows:

Mix solid raw materials such as praseodymium and neodymium metals, pure iron, and ferroboron in proportion.

The mixed raw materials are smelted through the smelting furnace, and then the quick-setting thin strip alloy sheet is formed by stripping.

The rapid-setting thin strip alloy flakes are crushed into coarse alloy powder through the secondary crushing furnace, and then fine alloy powder is made into alloy powder through jet milling.

Under the protection of nitrogen, the powder is made into a compact by pressing.

The compact is heated to a high temperature in a sintering furnace in a vacuum environment and then subjected to aging heat treatment to form a NdFeB blank.

Use professional equipment to process the blank according to the specific requirements of the order for shape and size, including grinding, wire cutting, slicing, punching, etc.

Cover the surface of the magnet with heavy rare earth metal or compound, and diffuse the heavy rare earth element into the interior of the sintered NdFeB magnet by heating

In order to meet the performance requirements of wear resistance and corrosion resistance, mechanical grinding and electrochemical treatment are carried out on the surface of the magnet.

According to the needs of the order, magnetize the magnet in the magnetic field using a magnetizer.

According to the requirements of the order, the magnetic properties, appearance, size, corrosion resistance and other properties of the magnets are inspected, and the packaging and storage can only be carried out after passing the inspection.

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances. Welcome to visit our sintered neodymium rod magnets factory in China.

The company applies technologies such as casting columnar crystal growth control technology, grain refinement and micro-optimization technology, etc., and is committed to improving the consistency of powder and giving full play to the performance potential of rare earth. By improving the smelting microstructure, applying fine-grain technology, and optimizing the mixing process, etc., significantly improving the performance of NdFeB magnets.

The company has applied and improved low-oxygen magnet preparation technology and cold isostatic pressing technology, so that NdFeB magnets are in a low-oxygen state during the pressing process, and the preparation of molding blanks is continuously optimized, which effectively reduces the loss of rare earth. The application of low-temperature sintering heat treatment technology has further improved the sintering process. Adjusting the temperature to a suitable state can give full play to the performance of the formula. The representative products are high-performance N55 magnets prepared by low-oxygen technology and N38UH magnets produced by near-net molding technology.

In order to pursue the accurate precision of customer customization, the company applies high-performance ultra-thin small special-shaped permanent magnet preparation technology to carry out high-efficiency and low-loss precision machining of NdFeB blanks, breaking through the technical bottleneck of high-performance thin and small magnet processing difficulty, and Strictly control product appearance defects through intelligent image appearance automatic inspection technology to improve inspection efficiency and accuracy.

Permanent magnets maintain their magnetic properties over time due to their unique atomic structure ...

NdFeB countersunk magnets have become a key component in many magnetic connection systems due to the...

In the world of modern electronics, ferrite magnets have emerged as a crucial component in the desig...

With the rapid development of modern science and technology, the application of NdFeB magnets in man...

Working Principle of Ferrite MagnetsThe main component of ferrite magnets is a composite of iron oxi...

Ferrite Disc Magnet is widely used in many fields due to its excellent magnetic force and unique pro...